Fluoropolymer extruded pipe

Polymers have the following outstanding properties:

• Excellent chemical resistance • Does not absorb water

• Temperature range from -200 degrees to 260 degrees • Resists UV

• Corrosion resistance • Non-flammable (UL94 V-0)

• Low coefficient of friction • High purity (no pollution to aromatic solvents)

• Electrical insulation properties • No physical hazards, non-toxic

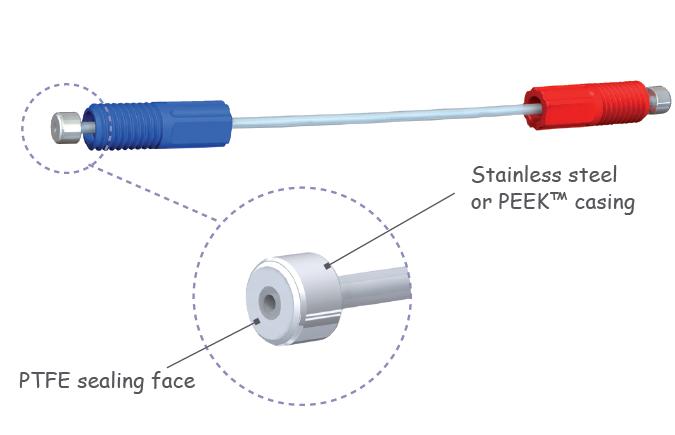

CB combas has been supporting the production and use of fluoropolymer materials as a conventional pipe for custom flanging lines since 2012. The main products are polytetrafluoroethylene (PTFE), perfluoroalkoxy (PFA), fluorinated ethylene propylene (FEP), polyvinylidene fluoride (PVDF) and ethylene-tetrafluoroethylene (ETFE) Polymer catheters, ranging from microtubes with an internal diameter of 0.1 mm to catheters with an internal diameter of 120 mm, have wall thicknesses from 0.05 mm to 5 mm. The use of various testing equipment for line data acquisition, including thermal, mechanical and electronic high performance and other aspects, real-time continuous ultrasonic measurement of inner diameter, outer diameter, wall thickness, concentricity, ellipticity, to provide customers with high precision, microporous With a small tolerance of the catheter, our products are suitable for use in a variety of harsh environments. Our products are compliant with RoHS regulations. We can also provide FDA-compliant, UL224-certified and USP-grade raw materials. All of these fluoropolymers are made from materials such as Teflon, Tefzel, Kynar, Solef, Neoflon, Fluon, etc. We provide products with high purity and stability as much as possible. The standard catheter is a natural color, we can provide custom services such as color, logo printing and so on. PTFE conduits can be used in almost all chemicals, solvents and corrosive materials, even in internal, external high temperature environments, and can be vaporized, chemically or autoclaved.